Service Hotline

400-0531-311 / 0531-87253877

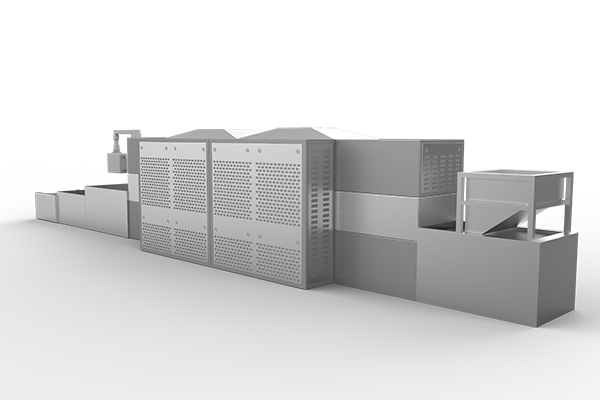

The tea curing and drying equipment uses the principle of microwave heating. During the heating process, the tea is heated, dehydrated, softened, volatilized the smell of grass, purified enzyme activity, and the appearance is emerald green.

The equipment design is reasonable, the structure is compact, the performance is reliable, the operation is simple, and the maintenance is convenient. Compared with the traditional method of teasing and drying, it has the following advantages:

1. Heating speed: the microwave directly heats the inside and outside of the tea at the same time, without preheating, it can be processed after turning on the machine. In traditional production, a preheating process is required.

2. Uniform heating: Microwave curing and drying means that the electromagnetic waves generated by the magnetron are uniformly irradiated to the tea, and the inside and outside are heated at the same time, without burnt leaves, burnt edges, debris, etc., while the traditional tea curing is done by heating the drum Then it is transferred to the tea and the heat is uneven, which is easy to produce outside ripeness and inside growth, dry outside and wet inside. It has a burnt smell, burnt leaves, and debris, which seriously affects the quality of tea.

3. Less nutrient loss of tea: The tea stays in the microwave heating box for a short time, and it does not require air and steam to conduct heat, so it can retain the nutrients in the tea to the greatest extent, and it is durable. And the staying time in the dryer is longer, so the nutrients in the tea are lost more.

4. The effect of sterilization and alcoholization is great: during the picking and production process of tea, there is often the possibility of secondary pollution. Microwave quenching and drying have the functions of sterilization and alcoholization. Traditional process equipment does not have this function. Microwave is special For summer and autumn tea, it is quite effective in addition to the bitter and astringent taste. This mellow function cannot be substituted by other machinery.

5. Reduce labor intensity and improve work efficiency: This equipment adopts automatic loading and unloading. The operator only needs to press the button to monitor the operation of the equipment and inspect the degree of fresh leaves. It only needs to be completed and dried. 1-2 people.

Email: jnyuehong@163.com

Fax: 0531-85705751

Service Hotline: 400-0531-311 /0531-87253877 /0531-87253677

Company Address: No. 48, Huangshan Community, Pingan Street Office, Changqing District, Jinan City, Shandong Province