Service Hotline

400-0531-311 / 0531-87253877

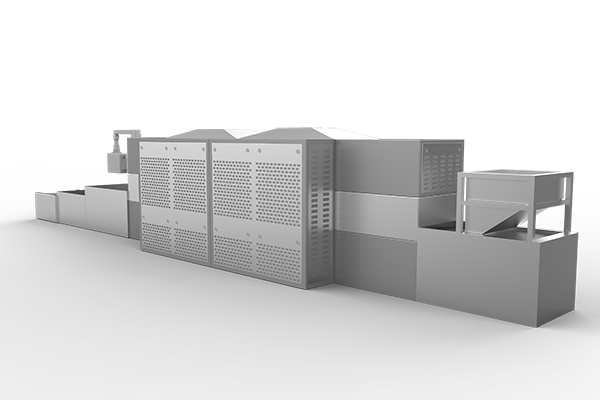

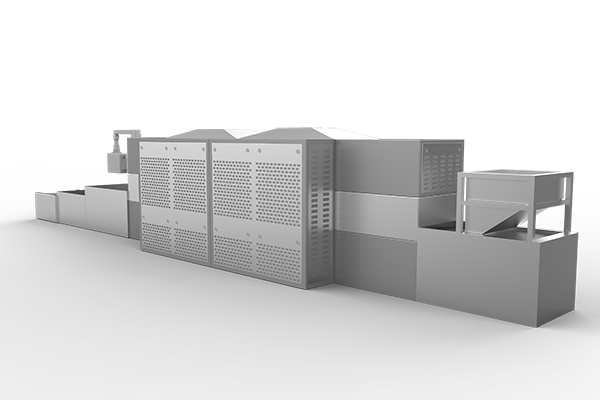

Microwave ceramic drying equipment is mainly used in honeycomb ceramics, craft ceramics, high-voltage insulating ceramics, special ceramic powders, and electronic material powders for shaping and drying.

Conventional heating, such as flame, hot air, electric heating, steam drying, etc., all use the principle of heat conduction to transfer heat from the outside of the heated object to the inside, and gradually increase the center temperature of the object, which is called external heating. It takes a certain time for the central part to reach the required temperature, and it takes longer for objects with poor thermal conductivity. These traditional drying methods have a long time, high power consumption, uneven heating, up and down, and high labor intensity. Microwave drying can avoid this situation well. Microwave can penetrate the inside and outside of the object and heat at the same time. It is 2450MH, with 2.45 billion oscillations per second, the molecules rub against each other to generate heat, and their own substances absorb waves and heat each other.

The characteristics of microwave ceramic drying and shaping equipment are:

1. The quality of the product is good when it is dried and shaped without cracking. Ceramic powder microwave drying equipment

2. Easy to control, convenient and flexible operation.

3. Time saving and high output.

4. Less energy consumption.

5. Small production intensity and less land occupation.

6. It is labor-saving and process-saving, and it is easy to connect to the front and back processes into an automatic line, reducing the number of handling.

7. Environmental protection and sanitation. There will be no "three wastes" problem.

Email: jnyuehong@163.com

Fax: 0531-85705751

Service Hotline: 400-0531-311 /0531-87253877 /0531-87253677

Company Address: No. 48, Huangshan Community, Pingan Street Office, Changqing District, Jinan City, Shandong Province