Service Hotline

400-0531-311 / 0531-87253877

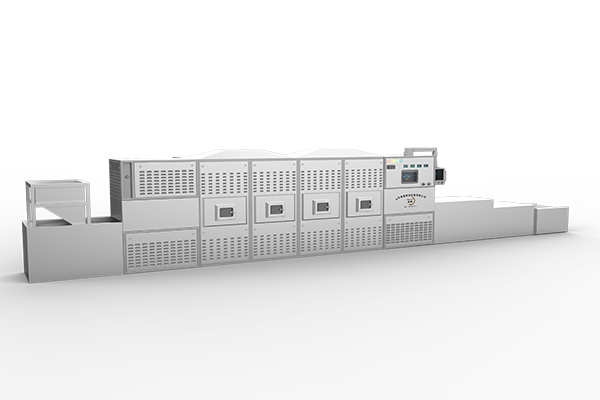

Features of microwave drying and sterilizing equipment for instant noodles:

1. Uniform heating and high efficiency

Conventional methods (such as hot air, steam, etc.) transfer heat from the surface of the material to the inside through convection, conduction or radiation, so the speed is slow and there is uneven heating between the surface and the inside. Microwave heating uses the polar molecules in the material under the action of microwave electromagnetic field to directly heat the surface and the inside of the material at the same time, so the heating is uniform, the thermal efficiency is high, and the speed is fast. It is 2 to 4 times more efficient than the conventional heating method. The degree of change is further.

2. Product quality assurance

Compared with the products processed by the conventional method, the instant noodles processed by microwave are fuller, with higher gluten value, good rehydration, better color and taste, smooth and elastic. It not only maintains the flavor of traditional noodles, but also keeps continuous when rehydrating. It is resistant to boiling, not muddy soup, and does not destroy the original nutrients.

3. Easy to control, convenient to match with traditional instant noodle processing technology

Since the power and transmission speed of the microwave equipment can be adjusted steplessly, there is no conventional thermal inertia problem when starting and stopping, and the reaction speed is fast, and it can be controlled in real time, adapting to different process requirements, and greatly reducing defective products or waste products. . The operation of the microwave equipment and the front and rear interfaces are synchronized with traditional instant noodle processing equipment.

Email: jnyuehong@163.com

Fax: 0531-85705751

Service Hotline: 400-0531-311 /0531-87253877 /0531-87253677

Company Address: No. 48, Huangshan Community, Pingan Street Office, Changqing District, Jinan City, Shandong Province