Service Hotline

400-0531-311 / 0531-87253877

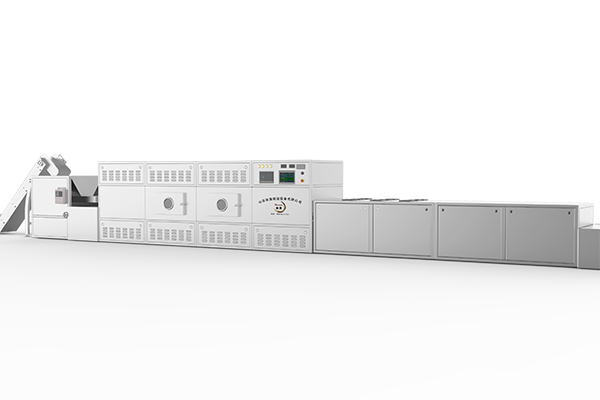

Introduction of Food Microwave Puffing Equipment

The microwave heating speed is fast, and the temperature of the gas (air) inside the material rises sharply. Due to the slow mass transfer rate, the heated gas is under pressure; and there is a tendency to expand. When the pressure is reached, the material will expand. For materials with high moisture content, a large amount of moisture evaporates in the initial stage of drying, which reduces the surface temperature of the product and the expansion effect is not good. When the moisture content is less than 20%, due to the increase in the viscosity of the material, the moisture and air in the internal voids of the material are more difficult to escape and are in a state of accumulation, which can produce a good puffing effect.

There are many factors that affect the puffing effect of materials. As far as the materials are concerned, those with loose structure and high fiber content are not easy to puff, and materials with high protein, high starch, high cavities or high pectin are "cured" after heating. , It has good film-forming properties, can wrap gas, and fix the foamed state after drying to get a good bulky product. A basic food formula with pullulan as the main raw material, supplemented with protein and electrolytes such as salt, can achieve the ideal puffing effect. The microwave heating process is supplemented by the method of reducing the pressure of the system to process puffed products.

Email: jnyuehong@163.com

Fax: 0531-85705751

Service Hotline: 400-0531-311 /0531-87253877 /0531-87253677

Company Address: No. 48, Huangshan Community, Pingan Street Office, Changqing District, Jinan City, Shandong Province